cone crusher telsimit

TELSMITH - Crushing and Screening

2020.2.4 Telsmith provides a full range of integrated processing equipment to the aggregate, mining, industrial, and recycling industries with cone crushers, jaw crushers,

Read More

Spare parts for Telsmith Cone Crushers - FLSmidth

Telsmith cone crusher spare parts and from EXCEL high performance parts have a longer wear life and improved efficiency and throughput. Our cone crusher spare parts are

Read More

Telsmith SBS圆锥破碎机零件 - crusher

查看零件数据库 查看产品照片 我们可以为Telsmith 38 SBS、44 SBS、52 SBS、57 SBS、68 SBS圆锥破碎机提供以下但不限于此的零件。 内衬套,外衬套,轧臼壁,破碎壁。

Read More

特史密斯圆锥破碎机零件 - CnCrusher" />

可选功能允许您监视和控制圆锥破碎机的操作参数,以产生最大的效率和一致的性能。. 我们使用离心铸造和砂型铸造机制造泰尔史密斯圆锥破碎机青铜零件。. 材料为标

Read More

EXCEL™ Replacement parts for Telsmith® Cone Crushers

2023.11.1 Telsmith® series cone crushers STM MODELS, FCTM MODELS, SBSTM MODELS Component identification Head Mainshaft Assembly Receiving Hopper Inner

Read More

Telsmith Titan™ Series Cone Crushers Manuquip

200hp (147kw) to 500hp (370kw) performance, highest-in-class crushing force. TitanTM Cone Crushers have large clearing circuits, and are designed to safely and quickly allow uncrushable materials to pass, avoiding costly

Read More

Telsmith 44 SBS Specifications Technical Data (2017-2021 ...

Telsmith 44 SBS Specifications Technical Data (2017-2021) Rate this machine now! Operating weight: 16.6t – Transport length: 2.6m – Transport height: 2.5m – Plant type:

Read More

Spare Parts Store in The Quarry, Mining, Cement ... - Echo

Echo Machinery Offers Telsmith® Cone Crusher Spare Parts. Telsmith serves the global mining and aggregate industries with crushing and vibrating equipment, modular stations,

Read More

Telsmith Supports Successful Titan T200 Cone Crusher

Wed March 18, 2020Telsmith Inc. Telsmith Inc., a manufacturer of mineral processing equipment, enjoyed a successful ConExpo-Con/AGG in Las Vegas, launching its Titan

Read More

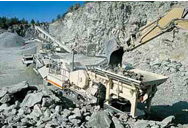

Telsmith builds high-capacity, track-mounted cone crusher

2011.2.24 Telsmith has developed a high-capacity, trackmounted, cone-crushing plant, the Tel-Trax TC52SBS, to work in conjunction with larger primary plants, such as

Read More

C-1540 Direct Drive Cone Crusher Mobile

2024.1.16 The fuel efficient direct drive Finlay® C-1540 Cone Crusher is the optimum machine for medium sized producers and contract crushing operators. This efficient and productive machine features the

Read More

McLanahan CMB Cone Crushers

Below are suggested speed guidelines for CMB Cone Crushers: Low speed: Secondary applications, after a Jaw Crusher. Medium speed: Gravel applications with coarse feed. Standard speed: Tertiary applications (0 x 1/2”) High speed: Sand applications (4m or less) Speed ranges: Smaller head diameters (48” or smaller): 750-1,200 rpm.

Read More

TELSMITH - Crushing and Screening

2020.2.4 cones are available with the TRAC 10® automation control package. Available from 300 HP (220 kW) to 500 HP (370 kW). TRAC10® AUTOMATION TRAC10® is a stand-alone control system that monitors crusher operations, provides automated calibration and setting controls, and protects the crusher from overload; all

Read More

Sandvik Cone Crushers - SRP

Sandvik cone crushers are an excellent choice in secondary, tertiary, quaternary and pebble-crushing applications. They are equipped with the hydraulic Hydroset™ system, which provides safety and setting-adjustment functions. Our crusher automation system delivers real-time performance management, enabling you to monitor and optimize

Read More

Cone Crusher Liners: How to Select and When to Change

2020.6.23 90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two. 40-60% passing the midpoint. 0-10% passing the closed-side setting. A well-graded feed to the Cone Crusher. You want to match the entire feed gradation, not just the feed size, so that you utilize the entire chamber.

Read More

CS系列圆锥破碎机

2014.9.15 that the CS series cone crusher wins the reliance of all customers by its superior performance, reliable quality and high cost performance, and it is the ideal substitute of traditional cone crusher. 产品简介 Brief Introduction SKJ Series Jaw Crusher CS系列圆锥 02

Read More

Maximize your cone crusher productivity Pit Quarry

2017.4.28 Providing better crusher feed control for the cone crusher through the use of surge piles, hoppers and variable-speed feeding devices such as belt conveyors or vibrating pan feeders can easily increase crusher productivity by a minimum of 10 percent. Metso’s Lokotrack LT220D combines a crusher and screen onto the same chassis.

Read More

Patriot® Cone Crusher Secondary or Tertiary Crusher

3 天之前 Superior’s Patriot Cone Crusher is an American-made, bushing-style rock crusher that sets the standard for productivity and durability. With a lifetime warranty and high-grade, industry-exceeding components, the Patriot Cone delivers reliable performance and unbeatable value in secondary or tertiary applications.

Read More

Our Range of Trio® Cone Crushers Weir

A cone crusher is a type of crusher that is commonly used for processing rocks in mining and aggregate applications. These crushers use compression force to break large rocks (and other materials) into smaller rocks, gravel and sand.. Since its inception, the live-shaft cone crusher design is highly regarded as the benchmark for reliable hard rock cone

Read More

Cone Crushers (Parts of a Cone Crusher) Explained - saVRee

The spring cone crusher design is able to pass uncrushable materials e.g. tramp metal, through the crushing cavity by using springs. The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of the crushing cavity hydraulically, instead of using springs (mechanical actuation). Both the spring and hydraulic cone ...

Read More

【Rocky DEM4.5案例八】圆锥破碎机_哔哩哔哩_bilibili

2022.1.23 大家围观的直播. 【Rocky DEM4.5案例八】圆锥破碎机, 视频播放量 2531、弹幕量 0、点赞数 19、投硬币枚数 4、收藏人数 60、转发人数 5, 视频作者 口算N-S方程, 作者简介 公眾號 从入门到秃头krr 秋秋裙743393650 可配工作站,相关视频:AnsysRocky-将多物理仿真扩展到颗粒 ...

Read More

A review of modeling and control strategies for cone crushers

2021.8.15 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher. The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017).The maximum distance between the mantle and concave, on the other

Read More

Spare parts for Telsmith Cone Crushers - FLSmidth

Key Benefits. Telsmith cone crusher spare parts and from EXCEL high performance parts have a longer wear life and improved efficiency and throughput. Our cone crusher spare parts are improved over OEM standards, allowing for

Read More

concasseur à c?ne telsimit

telsimit concasseur à c ne alexandreresourcecenter . Concasseur à c?ne, y compris concasseur à c?ne de HCS vérin hydraulique peut être utilisé comme concasseur secondaire et concasseur tertiaire. Obtenez le prix; o amp m manual cone crusher otsuka cc Cone Crusher Manuial. 48s TON concasseur à c ne manuel en pdf.

Read More

(PDF) Study on the technical parameters model of the

2022.5.25 A cone crusher is a machine that crushes rock materials with high efficiency and low power consumption; it is one of the typical road construction equipment. To improve the production efficiency ...

Read More

Crushing 101 – Different types of crushers for distinctive needs

2020.12.17 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

Read More

(PDF) Telsmith SBS Cone Crushers Jorge Bravo

telsmith SBS CONE CRUSHERS 65777_791-03 04-TEL-002dd 1 03/07/2005 6:36:03 AM the telsmith difference the trusted solution Mineralandaggregateprocessorsworldwide TheTelsmithDifferenceisacommitmenttoinnovative

Read More

Sandvik CS660 Cone Crusher For High Capacity Applications

622.0 mm (24.5 in.) 315 kW (422 hp) Sandvik CS660 cone crusher has a hydraulically supported main shaft that is supported at both ends. It also has a robust crusher design, adjustable eccentric throw, and a constant intake opening. This crusher is suitable for a high-capacity secondary crushing application.

Read More

What Is a Cone Crusher and What Can It Do for You?

2021.1.10 Eagle Crusher recently unveiled its own offering of Raptor® cone crushers at CONEXPO-CON/AGG 2020, North America’s largest construction trade show. Our team is currently offering the 250, 350, and 450 model Raptor® cone crushers for customers. If you are interested in a cone crusher, please contact a Team Eagle sales representative.

Read More

Cone Crusher Hazemag North America

990. 1050. 1175. 1280. 1380. 1480. Contact Us. The CYBAS-i Cone crusher is a modern high performance hydraulically adjusted (hydroset-type) cone crusher, an enhancement of the original legendary CYBAS Cone. It is the result of intensive research and development of the crushing chamber and mechanical design.

Read More

China Crusher, Crusher Wholesale, Manufacturers, Price

The cost of a Crusher can vary widely depending on its size, capabilities, and complexity. Most of the price of Crusher ranges from US $ 299 to $ 299999 per Piece. It's important to research and compare different models and features to

Read More

Calaméo - PARTS CATALOG

2 天之前 Telsmith SBS Cone Crusher Parts Catalog Model 44 09/06 67 NAMEPLATES, LABELS AND DECALS — CRUSHER (Refer to Figure 27) Item No. Part No. Description Qty 2701 AB-46-3020 LABEL, Crushing

Read More

Nordberg HP Series cone crushers – High performance

2022.1.21 The world's most popular modern cone crushers. Nordberg HP Series cone crushers bring together the optimal combination of crusher speed, throw, crushing forces and cavity design. As the name suggests, these proven and reliable universal crushers deliver High Performance in quarrying and mining applications.

Read More

Cone crusher basics in 4 minutes - rockprocessing.sandvik

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing ...

Read More

Crusher Liners Cone Crusher Liners Crushing Wear Parts

Crusher Liners. CSP is a leading supplier of cast, forged, and fabricated wear solutions to OEM and aftermarket crusher operators. We have over 30 years’ experience supplying crushing wear parts to global mining and mineral processing, oil sands, steel, cement, power and aggregate customers. We supply crusher liners and wear parts with ...

Read More

Influence of Two Mass Variables on Inertia Cone Crusher

2021.2.4 Inertia cone crushers are widely used in complex ore mineral processing. The two mass variables (fixed cone mass and moving cone mass) affect the dynamic performance of the inertia cone crusher. Particularly the operative crushing force of the moving cone and the amplitude of the fixed cone are affected, and thus the energy

Read More

sbm/sbm teismits 24 in spring cone crusher.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Read More

fe 24 telsimit crusher

Station Mobile de Concasseur Combinatoire Type: concasseur primaire Taille dalimentation: 0-350mm Matriel traiter: minerai de fer, minerai de cuivre, minerai dor, minerai de manganse, calcaire, granit, basalte, quartz, silice, gypse, roche...

Read More

Minerals Free Full-Text An Improved Capacity Model of the Cone ...

2022.2.11 The capacity of the cone crushers was investigated theoretically by many scholars. Gauldie [2,3] proposed an empirical model of capacity by analyzing the structure of various crushing equipment.Briggs [4,5] and Bearman [] presented a theoretical model of cone crusher capacity by evaluating the influence of mantle motion on the falling motion

Read More

- سنگ شکن فکی بخش مواد

- تفاصيل عن ميلز في الصين

- زائد دي لغة سور الحلوى سحق

- تستخدم المملكة المتحدة باركر الفك محطم

- مواقع شراء معدات بناء معامل الطابوق غربية المنشأ

- كسارة الحجر المحجر للبيع في الولايات المتحدة الأمريكية

- أطلس كسارة صخور كوبكو

- ژوهانسبورگ معدن زغال سنگ

- فرز نمک و کارخانه ید برای فروش

- كسارة رقاقة عمودي

- vsi محطم الإمارات العربية المتحدة للبيع

- گیاه شستشو برای کانادا شن و ماسه

- المواد التقطيع في الإكوادور

- طاحونة الذهب المكثف الطرد المركزي

- الكرة مطحنة limetreat شبكة التنمية المستدامة دينار بحريني