cone crusher drawin

Cone Crusher - Free 3D CAD Models, 2D Drawings, and

2017.10.30 Download the model according to the specified sizing parameters in either 3D or 2D format. Dassault Systèmes 3D ContentCentral is a free library of

Read More

Cone Crusher - an overview ScienceDirect Topics

Sketch of a Secondary Cone Crusher. The breaking head gyrates inside an inverted truncated cone. These crushers are designed so that the head-to-depth ratio is larger

Read More

cone-crusher 3D CAD Model Library GrabCAD

2011.12.4 Cone crushers are actually very interesting machines. I designed and manufactured spiral bevel gear set for MP1000 crushers for Metso in 2008. Made it possible in a small size shop thanks to right CAD

Read More

Cone crusher in AutoCAD Download CAD free

Cone crusher. Viewer. Oscar emerson sivincha paucar. Ore comminution section mining equipment for size reduction. Library. Machinery - mechanical. Mining industry. Download dwg Free - 343.58 KB. 3.7k Views.

Read More

Cone crusher modelling and simulation using DEM

2016.1.1 Cone crusher modelling and simulation using DEM - ScienceDirect Minerals Engineering Volume 85, January 2016, Pages 92-105 Cone crusher modelling and

Read More

A review of modeling and control strategies for cone crushers

2021.8.15 We review the state of the art developments in process modeling and cone crusher control from 1972 to 2020. • The steady-state model of Whiten (1972) is still used

Read More

cone crusher 3d models 【 STLFinder

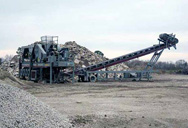

Cone Crusher Machine Dirty 3d model. cgstudio. Cone Crusher Machine Dirty crushing device.Cone crusher is a machine designed to reduce large rocks into small gravel, sand

Read More

Schematic diagram of a cone crusher (after [2] Figure 6.3 ...

Philip Hingston L. Barone L. While This paper describes the use of an evolutionary algorithm to solve an engineering design problem. The problem involves determining the geometry

Read More

CONE CRUSHER MODELLING AND SIMULATION

2019.7.3 Jehander Sand Grus AB. A Svedala H6000 crusher operating as a secondary crusher stage has been tested at five different close side settings (CSS). A

Read More

Design and Analysis of Modified Base Frame of a Cone Crusher

2021.2.1 Cone crusher is a size reduction mechanical equipment which crushes the large sized limestone and dolomite particles by squeezing it between gyrating spindles.

Read More

CS系列圆锥破碎机

2014.9.15 that the CS series cone crusher wins the reliance of all customers by its superior performance, reliable quality and high cost performance, and it is the ideal substitute of traditional cone crusher. 产品简介 Brief Introduction SKJ Series Jaw Crusher CS系列圆锥 02

Read More

Constant Wear Criterion for Optimization of the

2024.1.15 Minerals 2022, 12, 807 3 of 21 2. Particle Crushing Pressure Model of the Crushing Chamber The crushing chamber of a cone crusher is composed of the mantle and concave.

Read More

McLanahan CMB Cone Crushers

Below are suggested speed guidelines for CMB Cone Crushers: Low speed: Secondary applications, after a Jaw Crusher. Medium speed: Gravel applications with coarse feed. Standard speed: Tertiary applications (0 x 1/2”) High speed: Sand applications (4m or less) Speed ranges: Smaller head diameters (48” or smaller): 750-1,200 rpm.

Read More

Jaw Crusher VS Cone Crusher (A Comparison From 7 Points)

2023.5.27 The overall structure of the machine. From the perspective of the overall structure, the cone crusher is 1.7-2 times heavier and 2-3 times higher than the jaw crusher with the same feeding opening size. A Larger machine means

Read More

Cone Crusher Liners: How to Select and When to Change

2020.6.23 90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two. 40-60% passing the midpoint. 0-10% passing the closed-side setting. A well-graded feed to the Cone Crusher. You want to match the entire feed gradation, not just the feed size, so that you utilize the entire chamber.

Read More

C-1540 Direct Drive Cone Crusher Mobile Tracked Crusher

2024.1.16 The fuel efficient direct drive Finlay® C-1540 Cone Crusher is the optimum machine for medium sized producers and contract crushing operators. This efficient and productive machine features the proven Finlay® 1000 cone crusher that is choke fed with integrated level sensor, automatic tramp relief and hydraulic closed side setting (CSS ...

Read More

Cone-Crushers圆锥破碎机大学毕业论文外文文献翻译及原文.doc

2017.2.22 毕 业 设 计(论文) 外 文 文 献 翻 译 文献、资料中文题目:圆锥破碎机 文献、资料英文题目:Cone Crushers 文献、资料来源: 文献、资料发表(出版)期: 院 (部): 专 业: 机械设计制造及其自动化 班 级: 姓 名: 学 号: 指导教师: 翻译期: 2017.02.14 本科毕业设计外文资料翻译 系 别 ...

Read More

Ice Cream Drawing: How To Draw An Ice Cream Cone Caribu

2021.10.7 Step One: Draw The Ice Cream. Once you are all set up and ready to draw, the first step is to draw the ice cream. Start near the top of the page. Draw a circle that is open at the bottom. The best way to do this is to draw the letter C with the opening facing down. The size of your ice cream will determine the size of the rest of the drawing ...

Read More

Cone Crusher - Free 3D CAD Models, 2D Drawings, and

2017.10.30 Download the model according to the specified sizing parameters in either 3D or 2D format. Dassault Systèmes 3D ContentCentral is a free library of thousands of high quality 3D CAD models from hundreds of suppliers. Millions of users download 3D and 2D CAD files everyday.

Read More

cone-crusher 3D CAD Model Library GrabCAD

2011.12.4 cone-crusher 3D CAD Model Library GrabCAD. Join 9,320,000 engineers with over 4,830,000 free CAD files Join the Community. The CAD files and renderings posted to this website are created, uploaded and managed by third-party community members. This content and associated text is in no way sponsored by or

Read More

Sandvik Cone Crushers - SRP

Sandvik cone crushers are an excellent choice in secondary, tertiary, quaternary and pebble-crushing applications. They are equipped with the hydraulic Hydroset™ system, which provides safety and setting

Read More

Influence of Two Mass Variables on Inertia Cone

2021.2.4 Inertia cone crushers are widely used in complex ore mineral processing. The two mass variables (fixed cone mass and moving cone mass) affect the dynamic performance of the inertia cone crusher.

Read More

Patriot® Cone Crusher Secondary or Tertiary

3 天之前 Superior’s Patriot Cone Crusher is an American-made, bushing-style rock crusher that sets the standard for productivity and durability. With a lifetime warranty and high-grade, industry-exceeding components, the

Read More

Open source alternatives to AutoCAD Opensource

2017.11.13 BRL-CAD. BRL-CAD is a cross-platform CAD tool that dates back to 1979, although it would take 25 years for the source code to be released under an open source license. In fact, BRL-CAD is so old that it has been credited with being the oldest source code repository of an application currently in active development.. Originally

Read More

【Rocky DEM4.5案例八】圆锥破碎机_哔哩哔哩_bilibili

2022.1.23 大家围观的直播. 【Rocky DEM4.5案例八】圆锥破碎机, 视频播放量 2531、弹幕量 0、点赞数 19、投硬币枚数 4、收藏人数 60、转发人数 5, 视频作者 口算N-S方程, 作者简介 公眾號 从入门到秃头krr 秋秋裙743393650 可配工作站,相关视频:AnsysRocky-将多物理仿真扩展到颗粒 ...

Read More

MATHEMATICAL MODELING OF GRAIN SIZE AND

2021.4.20 SHAPE OF CONE CRUSHER Shuguang Zhang Institute of Applied Mathematics, Jiaozuo Normal College, Jiaozuo City, Henan Province 454000, China. Email: zhangshuguangjz@yeah ABSTRACT: In order to quantitative analysis and calculation of cone crusher broken material quality to support the optimization design of the product,

Read More

Crushing 101 – Different types of crushers for distinctive needs

2020.12.17 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

Read More

Our Range of Trio® Cone Crushers Weir

A cone crusher is a type of crusher that is commonly used for processing rocks in mining and aggregate applications. These crushers use compression force to break large rocks (and other materials) into smaller rocks, gravel and sand.. Since its inception, the live-shaft cone crusher design is highly regarded as the benchmark for reliable hard rock cone

Read More

Nordberg HP Series cone crushers – High performance

2022.1.21 The world's most popular modern cone crushers. Nordberg HP Series cone crushers bring together the optimal combination of crusher speed, throw, crushing forces and cavity design. As the name suggests, these proven and reliable universal crushers deliver High Performance in quarrying and mining applications.

Read More

Energies Free Full-Text Influence of Operating Conditions

2018.5.1 To verify the model of energy consumption, industrial experiments were conducted on a PYGB1821 cone crusher at Anshan Iron and Steel Group Mining Co., Ltd. (Anshan, China). Energy consumption, feed size distribution, and structural parameters of the crushing chamber were measured. Table 1 shows the energy consumption of the

Read More

Cone Crushers (Parts of a Cone Crusher) Explained

The spring cone crusher design is able to pass uncrushable materials e.g. tramp metal, through the crushing cavity by using springs. The first hydraulic cone crusher was developed in 1948 and this allowed for the opening of

Read More

Types of Crushers: What You Need to Know - Machinery

Cone crushers are one of the main choices for secondary crushing. A cone crusher is a powerful machine that is used in large-scale industries for crushing various types of materials into smaller sizes. It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and force. The crushed material ...

Read More

MCC Series Cone Crusher Minyu Machinery Corp.

2023.8.7 MCC Cone Crusher. There are generally four types of Standard Cone Crushers: the MCC Standard or Coarse type, the MCF Fine or Medium type, the MCS Short Head type MCSS Super Fine type. All four types are designed for secondary or tertiary crushing purposes both in stationary and portable applications for highly abrasive materials.

Read More

Schematic description of the crushing plant, (1) primary crusher

This method simulated the complete crushing process of the cone crusher and realized loop optimization. Moreover, researchers have proposed the empirical model (Eloranta and Evertsson, 2006), the ...

Read More

(PDF) Design and Analysis of Modified Base Frame of a Cone Crusher

2021.2.1 Cone crusher is a size reduction mechanical equipment which crushes the large sized limestone and dolomite particles by squeezing it between gyrating spindles. Crusher must be mounted on a frame ...

Read More

A review of modeling and control strategies for cone crushers

2021.8.15 The minimum distance between the mantle and concave is defined as the closed side setting (CSS) of the cone crusher. The CSS is easily changed online in a large variety of commercial crushers; different principles of CSS adjustment are described in (Quist, 2017).The maximum distance between the mantle and concave, on the other

Read More

Cone Crusher SpringerLink

2023.5.3 Cone Crusher. Cone crusher is a type of crushing equipment whose crushing cone rotates in the conical cavity within the shell to realize intermediate crushing or fine crushing of material through squeezing, bending, shearing, and impacting. At the end of the nineteenth century, the Simons brothers of the USA invented this equipment based

Read More

Rotor Blade Design, Number of Blades, Performance

2021.11.17 Introduction. The design of the blade planform relates to the choices about the main geometrical characteristics of the blade, namely, chord, twist and blade thickness. In addition to these main quantities, the blade sweep, prebend and cone angle can be considered part of the planform design, though from a purely aerodynamic point

Read More

DEM-based design of feed chute to improve performance of cone crushers ...

2021.7.1 The effect of feed chute design on tertiary cone crusher performance at the Sarcheshmeh copper complex was studied by an in-house developed DEM software called KMPC DEM ©. To simulate the overall crushing circuit, the multi-geometry procedure by improving the routines of object files importing into the simulation environment was

Read More

- 10MM كسارة الحجر الجيري

- الجناح مطحنة الشركة المصنعة الهند

- عملية طحن الكهروكيميائية تحميل الفيلم

- محطم نظرة عامة الحجر الجيري

- ماكينات تعدين ومناجم الذهب في أستراليا

- كسارات الصخور المستخدمة في استخراج الذهب

- ماشین سنگ زنی گوجه فرنگی خشک

- الهيدروليكي واحد محطم الحجر

- دانلود رایگان iconveyorseminartopic

- مخروط جودة كسارة كسارة الفك

- تصميم الحزام الناقل الجير

- تستخدم ذروة سعر المعدات في أوروبا التغذية

- طاحونة الأسمنت الدائرة المفتوحة

- تستخدم الكسارات للبيع في دبي الهند

- مطحنة المطرقة الكالسيت للبيع