compaction equipment construction

The pioneer of intelligent construction—An overview

2022.12.1 As the pioneer in the intelligent construction technologies (ICT) of transportation infrastructure, intelligent compaction (IC) has been applied in the

Read More

CASE Compaction Equipment Products CASE Construction Equipment

Compaction Equipment. No two compaction jobs are the same. All three series of CASE vibratory rollers — double drum, single drum and pneumatic tire — provide operators

Read More

Compactors Cat Caterpillar

1 天前 Cat® Technology for construction helps contractors meet production goals and improve effi. Compacting to specifications is critical for soil, landfill, and paving

Read More

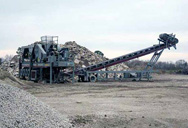

Types of Compaction Equipment and Their Applications

The goal of this article is to help you gain a deeper understanding of the compaction machinery options and when to use them. For a quick overview, the selection guide

Read More

Choose the Best Compaction Equipment for

4 天之前 Soil compaction takes place in almost every construction project. Construction crews use compaction equipment to increase soil density by reducing the spaces between or the amount of air within the soil

Read More

Soil Compaction Handbook - Multiquip Inc

2013.6.2 There are five principle reasons to compact soil: Increases load-bearing capacity Prevents soil settlement and frost damage Provides stability Reduces water

Read More

Compaction Equipment - Hitachi Construction Machinery

2024.1.20 Hitachi Construction Machinery offers a lineup of tired rollers and vibratory rollers that perform compacting and spreading of a surface for use in road construction

Read More

Compacting Characteristics of Light Compacting

2014.1.27 Various types of light compacting equipment like rammers, vibratory plate compactors, single-drum walk-behind rollers, and double-drum walk-behind rollers are being used for compaction of the materials

Read More

A framework for real-time compaction guidance system

2021.9.1 To ensure high-quality compaction, operators and site managers need to process a large volume of data in real-time. The high dependency of compaction quality

Read More

Know Your Compaction Facts For Construction Pros

2015.5.28 When selecting the right compaction machine for the job, proper soil identification is the best place to start. Soil is classified into two main categories: granular and cohesive. Granular soils ...

Read More

Compaction equipment - Off-Highway Research

Indian compaction equipment demand to regain former highs. The disruption of the 2019 general election and the impact of the Covid pandemic have seen sales of compaction equipment in India fall away from the high

Read More

Different Types of Soil Compaction Equipment:

Sheepsfoot rollers are used for compacting fine grained soils such as heavy clays and silty clays. Sheepsfoot rollers are used for compaction of soils in dams, embankments, subgrade layers in pavements and rail road

Read More

compaction equipment PPT - SlideShare

2016.10.8 7. Equipment for Compaction of soil. 8. EquipmentforCompactionofsoil Smooth wheel rollers Pneumatic rollers Grid rollers Tamping rollers Vibrating rollers Vibrating plates Vibratory compaction 8. 9. Smooth Wheel Rollers Smooth wheel rollers are one of the most common types of compaction equipment used.

Read More

Compaction Equipment; Pneumatic Tyred Rollers - Constro

2022.7.19 Dynapac CP1200W. The new pneumatic tyred roller is available with compaction width 2370 mm and a maximum operation mass of up to 30 000 kgs. It is ideally suited for a wide range of high-quality applications. The new models are built with a hydraulic transmission system, which simplifies steering and on-off operations.

Read More

15 Types of Compactors and When To Use Them BigRentz

2022.8.4 Finally, compaction equipment ties into the length and scale of a project. Longer projects with multiple phases may warrant more than one piece of compaction equipment. Should You Buy or Rent Compaction Tools? While some construction and landscaping teams keep plates or rollers on hand, compaction equipment rentals make

Read More

Compaction Equipment - Hitachi Construction Machinery

5 天之前 Compaction Equipment Pursuing optimum operating performance and enhancing operability and safety. Hitachi Construction Machinery offers a lineup of tired rollers and vibratory rollers that perform compacting and spreading of a surface for use in road construction and paving work. We pursue optimum operating performance in Hitachi

Read More

Compactors Cat Caterpillar

1 天前 Operating Weight - 11 Wheel Base Machine. 11685 lb. Operating Weight - 11 Wheel with Maximum Ballast. 32849 lb. 11 Wheel Compaction Width with Bias Tire. 84 in. View Details. Compare models. Soil Compactors.

Read More

Equipment > Compaction Equipment For Construction Pros

2023.11.7 VP-PC400 / 700 1000 Vibratory Plate Compactors. Kubota by Land Pride Plate Compactors for 3- to 8-ton excavators are ideal for trench, slope, and excavation compaction - well-suited for driving ...

Read More

Different types of Soil Compaction Equipment

2019.10.30 A soil compactor is a machine or mechanism used to reduce the size of material such as waste material or biomass through compaction. For the improvement of soil properties, e.g., density, water

Read More

7 Most Common Types of Compaction Rollers

2021.10.11 Smooth wheeled rollers, also known as static rollers, are a common type of roller that you often see at road construction and general construction sites. Smooth wheeled rollers are typically grouped into two

Read More

The Importance of Soil Compaction in Construction

2020.7.20 Types of Soil Compaction Equipment. Compaction equipment has been used in construction since the early 20th century. Steamrollers literally paved the way for today’s modern equipment. Soil compaction equipment comes in a variety of styles with different options such as single or double drums, vibratory mechanisms or dozer blades.

Read More

Compaction SpringerLink

2016.11.17 Compaction Equipment and Procedures. In the field, the soil for compaction purposes is excavated from a borrow area using power shovels, draglines, scrapers, and bulldozers. Once transported to the construction site, the soil is spread by bulldozers and graders, in layers 0.33–0.66 m (1–2 ft) thick, known as “lifts.” The

Read More

Compaction Equipment – Pavement Interactive

Compaction Equipment. There are three basic pieces of equipment available for HMA compaction: (1) the paver screed, (2) the steel wheel roller and (3) the pneumatic tire roller. Each piece of equipment compacts the HMA by two principal means: By applying its weight to the HMA surface and compressing the material underneath the ground contact area .

Read More

The Basics of Embankment Construction - Equipment

2018.11.5 When silty loams, silts, or loessial type soils are used or encountered in embankment construction, the moisture content should be controlled within -3 percent of the optimal moisture content. Field compaction tests should be performed on each lift. Before the next lift is placed, the required compaction must be obtained on the previous lifts.

Read More

6 Types of Rollers Commonly Used in Construction Projects

2019.12.27 For this to work, special construction equipment is needed to properly compact and smooth the ground. One of the most common types of compaction equipment is the road roller. Road rollers have a long history, with some of the first being pulled by a horse and used for agricultural purposes. In fact, modern rollers are still referred to as

Read More

30 Types Of Construction Equipment - Civiconcepts

1 天前 Power Shovel. 30 Types of Construction Equipment 33. There are three types of power shovels, crawler-mounted, truck-mounted, wheel mounted. It is used to excavate earth of all classes except rock and load it into the wagon. It has major parts mounting, cab, boom dipper stick, and hoist line.

Read More

How to Estimate Equipment Cost in Construction - Conplant

2023.8.19 Compaction equipment, such as rollers and compactors, literally help lay the groundwork for construction projects, ensuring structures are stable and upright thanks to stabilising soil and asphalt. This goes double for projects like road construction, where compaction equipment is the MVP.

Read More

Sustainability Free Full-Text Compaction Quality

2023.3.27 GeoGauge is a portable instrument for rapid determination of the stiffness and modulus of compacted soil, which can quickly, safely, and nondestructively evaluate the quality of each compacted layer. In order to deeply study the effectiveness of the detection instrument and equipment used in the soil-rock mixed subgrade, based on the

Read More

Use Proper Maintenance and Operation to ... - For

2009.2.28 The Bobcat R60P rammer is easy to use and built to last, delivering precise compaction in trenches and other tight work areas where other equipment can’t reach. Doosan Bobcat March 23, 2023

Read More

Choose the Best Compaction Equipment for

4 天之前 Construction crews use compaction equipment to increase soil density by reducing the spaces between or the amount of air within the soil particles. The process is helpful for all soil types. Compacted soil has a

Read More

Compacting In Small Spaces Construction Equipment

2015.3.27 Walt Moore, Editor “ Those who want to build must compact.” So begins Caterpillar’s Guide To Soil Compaction. The guide focuses primary on large rollers, but in the overall construction market, “those wanting to build” often are compacting with relatively small—but indispensable—machines: rammers, plate compactors, walk-behind rollers,

Read More

Intelligent compaction practice and development: a

2020.1.2 Design/methodology/approach. A bibliometric analysis on IC-relevant studies is presented. Through this quantitative manner, insights into the current IC research practice and development trends have been derived from the perspectives of publications and citations, spatial distribution, knowledge construction, structural variations, existing

Read More

The pioneer of intelligent construction—An overview

2022.12.1 Review of Chinese road construction machinery academic research-2.7 intelligent compaction technology and equipment. Journal of China Highway and Transportation, 6 (2018), pp. 56-61. Google Scholar. Xu, 2019. ... He is a world expert on pavement smoothness and intelligent compaction/construction technologies. His

Read More

Products - Hitachi Construction Machinery

4 天之前 With hybrid systems designed to reduce fuel consumption and ICT construction machinery enabling ICT construction work, we offer a range of products tailored to customer requirements. ... Compaction Equipment. Pursuing optimum operating performance and enhancing operability and safety. Mining. Hydraulic Excavators: operating weight of 100t

Read More

Compaction Test – Properties and Behavior of Soil – Online

This laboratory will employ the tamping or impact compaction method, known as the Proctor test, using the type of equipment and methodology developed by R. R. Proctor in 1933. Two types of compaction tests are routinely performed: (1) the standard Proctor test, and (2) the modified Proctor test.

Read More

Rent Soil and Dirt Compaction Equipment - United Rentals

2 天之前 Whether you need single and double drum rollers, rammers or plate compactors — for trenches, road construction paving, backfill, landfill or foundation work — we have the equipment to help you get the job done right. We have a full line of compaction rollers for rough terrain with durable padfoot rollers.

Read More

How to Pick Compaction Equipment for Your Construction Site

The Pro Group carries many of the most popular plate compactors, rammers, and rollers for every size job. Our experts can walk you through the selection process by helping you find the right compaction equipment fit for your job, whether you are looking to buy or rent. Request a quote or call us today at 1-888-776-0007 to speak with a ...

Read More

Development and Assessment of an Intelligent Compaction

2022.7.6 The successful quality control and quality assurance of compaction operations are vital for the long-term performance of earth structures. Traditional in situ measurement methods are in practice for assessing compaction project specifications. These methods have several shortcomings and cannot provide complete compaction

Read More

- أسعار ضواغط الذهب التعدين الصغيرة في جنوب أفريقيا

- محور عمودی آسیاب ضربه

- دي تلفيق دي TOUTES sortes دي CLS

- بهره برداری از سنگ آهن در خرد کردن و غربالگری

- jual MESIN محطم باتو kuarsa

- عمليات طحن بواسطة آلة طحن

- دراسة جدوى انشاء مصنع جبس بورد

- الصين الصلب لوحة حجر الفك محطم لسحق الحجارة

- آلة طحن جنوب أفريقيا نبات الفك سحق المحمول شبه ذروة

- مطحنه للمخلفات الزراعيه محليه الصنع

- مصنع كسارة فكية في اوزبكستان

- كسارة vsi في الأردن

- سنگ شکن سنگ معدن کوارتز معدن کارخانه و تجهیزات

- مطحنة الكرة بنغالور طحن

- مسحوق طحن internalgrinding